Introduction

The visit to the Envision Unlimited on October 2nd to the rose center was done in order to better understand what direction a project should take to help solve their problem. Various members from the four PRDV teams went to the observation, including Eda from GELI. From the start the fact that water spillage was an issue was known, later what type of problem the water posed was also revealed; when the tiles on the floor got wet, they could be damaged. Going to the Rose Center helped make clear when and how the water was spilled, and what current measures were currently being taken to mitigate tile damage. Knowing as much detail as possible is vital for such a project as to solve a problem it must be understood first.

Methodology

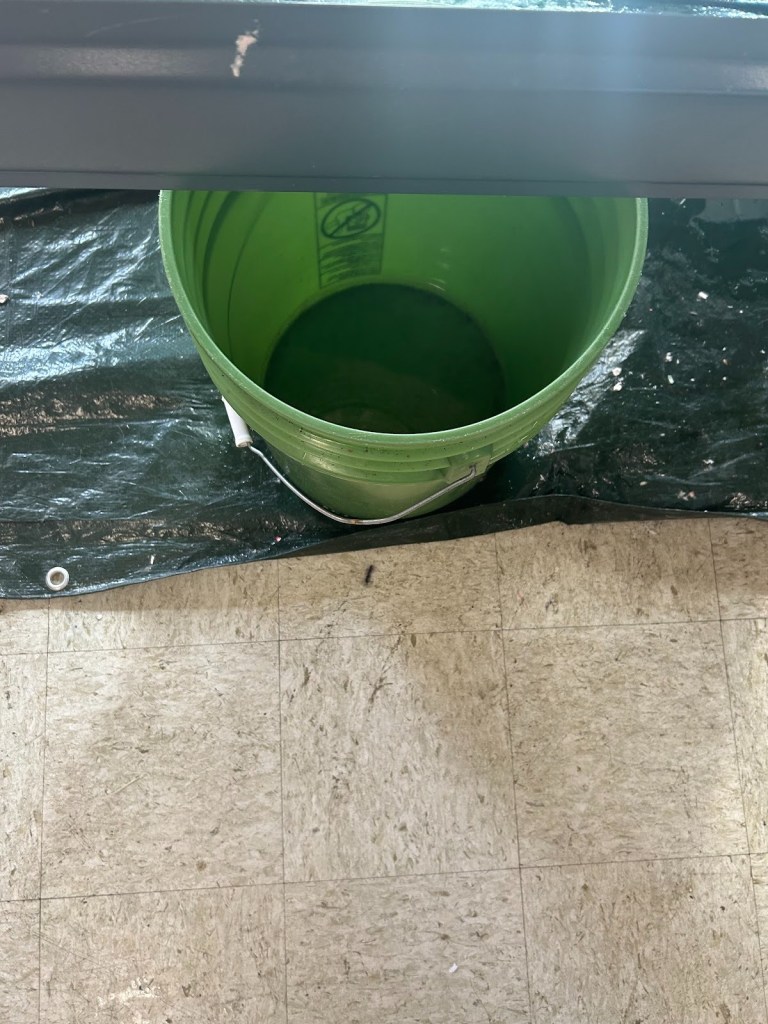

In order to gather information everyone involved in the meeting arrived at the envisioned unlimited center. Each person took turns asking questions. Many members from DTC section 3 traveled there to observe and ask questions, while a few members of envision unlimited demonstrated to us how they make paper. They brought in water with buckets filled by a hose on the outside of the building. Additionally, some paper scraps that came from paper that was previously made, but wasn’t an acceptable quality, were put into the filled tub. Before the papermaking started in ernest, everyone who was there asked for permission and then proceeded to take various measurements of the room.

Figure B 1. Different angles of pulp bucket

These are the measurements of the bucket used to contain the watery pulp that is then lifted up with the mould and deckle. The measurements of the bucket used to hold the pulpy water are 5.5 inches deep, 19 inches long, and 27.5 inches wide.

The teams took the opportunity to observe the papermaking process while also having chances to ask questions. Generally the observers stayed quiet and watched what was happening, while asking some questions occasionally.

Results

Through observations of the papermaking process, there are two ways water ends up on the tiles. The first is when a wet towel is put into the plexiglass sheets. This towel is used for the drying process of the paper where it is layered with felt to give an adequate location for the pulp to be placed on. However the bucket with the wet towels is across on the other side of the papermaking area from where the plexiglass sheets are. When the towel is lifted from its bin and carried across the tarp, a large amount of water spills onto the ground. This is a major issue that our teams must work towards alleviating to prevent the spillage of water onto the ground. Our team has to find ways to either catch this water, or keep it from being spilled in the first place.

Figure B 2. Photo of room

Figure B 2. Photo of room

Figure B 3. Towel on table for paper drying

Figure B 3. Towel on table for paper drying

Additionally, the second time when water is spilled on the ground is when the papers are left overnight to dry. The dripping continues overnight, and is one of the causes of the tile damage. Even from the short observation time available at the Rose center, water was seen collecting on the tarp. Buckets were placed to catch water spillage, but they did not cover all the places where water was dripping. The end of the tarp was right under the table where the papers were drying, and so water was dripping very close to the edge of the tarp where it could get onto the tiles.

Figure B 4. Bucket under table to catch water

Figure B 5. Water droplets on tarp

I asked a couple questions to Alex, one of the people giving us the demonstration. He told us that he enjoyed the papermaking process the way it was and that it did not need to change. He also told us in a later question that the towels and felt got heavy from being saturated with water.

During the papermaking process, paper pulp is placed onto the felt sheets from the mould and deckle. Around 6 rectangles of pulp are placed on the felt and then they are covered by a new sheet of felt. In total around thirty to forty sheets of paper are made from a pound of pulp. Additionally, sometimes the immersion blender would get stuck in the pulp.

Figure B 6. Pulp before it dries into paper

Figure B 6. Pulp before it dries into paper

The table with the pulpy water is 5 feet long and 2 feet wide. The papermaking screens are 9.5 inches long and 8.625 inches wide.

Discussion

A solution that solves the issues from water getting onto tiles has to address both times water spills into the ground. Additionally, this solution must not interfere with the process of the papermaking. The point isn’t to be as efficient as possible. One limit of the testing is that with so many people in the room, having observers may have been pressuring the demonstrators in a way that changed how they made the paper.